Heat Drying – Introducing control into your drying program

The DBK Drymatic System gives you, the water damage technician, a tool or combination of tools that can be used to significantly enhance the performance your water damage restoration programs. You are taught the importance of Humidity, Airflow and Temperature in any water loss program, however, Temperature is often overlooked and underestimated as a critical component in a fast, efficient and cost effective drying regime.

So why is temperature so important?

We are all familiar with creating the conditions to increase evaporation; reducing the humidity of the air and managing airflow and temperature. However, the bottleneck in drying is the removal of the bound water within the structure that dictates the duration of the drying process. Studies have shown that you can dehumidify the air in the drying chamber as much as you want but this does little to influence the diffusion rate of the water molecules held within the affected material. Diffusion rates can be influenced by manipulating the temperature of the wet material, making the water molecules within the structure more energetic and increasing the rate at which they move to the surface, where evaporation into the dryer (lower vapor pressure) air occurs.

Water can exist in three different phases; a solid, liquid and a vapor. When water leaves a structure due to evaporation (the phase change from a liquid to a vapor) it takes energy (heat) from the evaporating surface and this is referred to as evaporative cooling. Evaporative cooling is the reason why you can easily spot ‘wet’ areas on a thermal imaging camera; the ‘cold’ spots detected are potentially where water has evaporated from the structure and cooled the material it has left behind. The challenge for you, as a restorer, is to ensure that you are replacing the energy that is taken away during the evaporative process – failure to do so will result in a drop-off in the evaporative rate as the structure progressively gets cooler and the water molecules become less energetic.

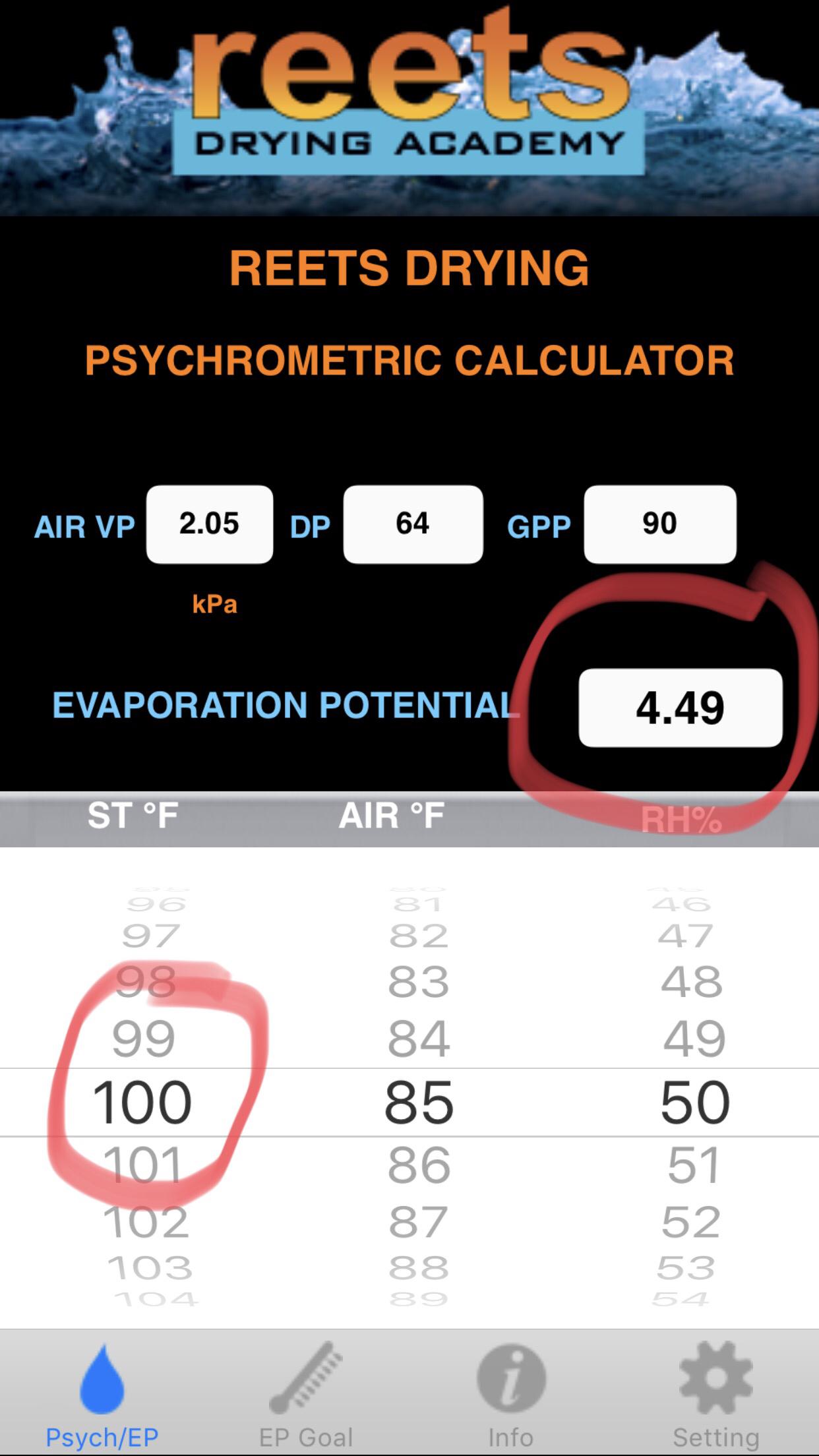

Effects of targeted heat drying on Vapor Pressure Differential (Evaporation Potential)